Since September 2018, the CED has offered, in addition to its multi-axis crash-testing and vibration expertise, a collaborative platform dedicated to the analysis of materials (safety, reliability and integrity).

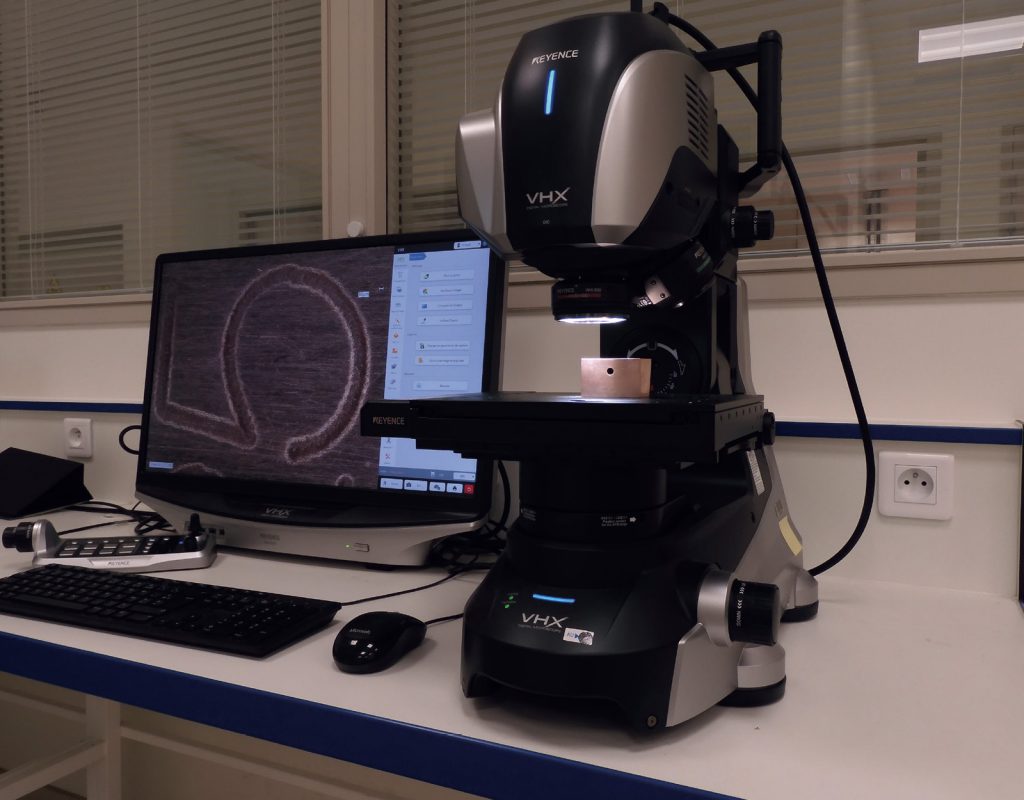

Metallurgy, heat treatment, mechanical behavior and tribology, this laboratory puts specialized technologies at your disposal, including a thermo-mechanical simulator (Gleeble 3500), a 3D digital microscope (VHX-7000), an interferometric microscope (Contour GTK A), a tribometer (UMT-Tribolab) and a glow discharge optical emission spectrometer (GD profiler 2).

Our activities

Innovation

- New material grades

- New process

- New products/benchmark

Materials

- Materials analyses: classical steels, sintered steels, tool steels, aluminum alloys, polymers and composites …

- Validation : sheets, tubes, wires, bars, screws…

Products

- Conformity of parts after test (durability, crash-test, specific validation test…)

- Support in case of emergencies: fracture surface analysis…

Characterization of materials and products after various processes

- Heat treatment: carbonitriding, quenching, nitriding, induction …

- Shaping: cutting, bending, stamping, fine blanking …

- Welding: laser, MAG, MIG …

- Assembly: screwing, riveting, gluing …

- Tube: geometry, defects …

Your needs / our solutions

You want to optimize your production processes with more suitable materials, you want to analyze with precision the causes and remedies for the failures of your products and materials so that your metal parts are safe, reliable and meet rigorous legal standards, our team of experts offers you the following services:

FAILURE ANALYSIS : We analyze the failure causes of your materials and propose you the most appropriate solutions to improve them.

- Fractography

- Wear in friction

MATERIAL CHARACTERIZATION: We characterize and expertise your materials before and after heat treatment in order to check especially their conformity to your specifications and international standards.

- Hardness

- Chemical composition

- Microstructures

- Mechanical properties

EXPERTISE IN TRIBOLOGY : Our expertise in friction, wear and lubrification will enable you to master and optimize surface states of your parts for a better compatibility in dry or lubricated friction.

- Geometrical characterization of surfaces (2D/3D)

- Physico-chemistry characterization of surface coatings

- Friction tests

- Optimization of the tribological triplet for a better friction

CHARACTERIZATION OF THERMO-MECHANICAL PROPERTIES OF METALS: The influence of the temperature on mechanical properties of metals is analyzed thanks to a thermo-mechanical simulator Gleeble unique in Normandy. It allows the reproduction of thermal cycles (from room temperature till 1700°C) with or without mechanical solicitations

- CCT diagrams (Continuous Cooling Transformation)

CHARACTERIZATION AND EXPERTISE IN WELDING: Our expertise in welding will enable you to control the quality of joints that secure the best mechanical strength.

EXPERTISE IN HEAT TREATEMENT : We evaluate the quality of your HT and propose you solutions to optimize it.

Our equipment

Our laboratory is equipped with advanced technologies:

- 2 optical microscopes

- 1 digital 3D microscope with articulated arm (VHX 7000)

- 1 scanning electron microscope (SEM) equipped with an EDS

- 1 glow discharge emission spectrometer (GD Profiler 2)

- 1 tribometer (UMT Tribolab): study of surface interactions

- 1 interferometric microscope (Contour GTK A)

- 1 universal tensile machine of 50 kN (tension, compression, bending-3-points)

- 2 microdurometers and 1 macrodurometer (Vickers, HRC, Knoop hardness)

- 1 thermo-mechanical simulator (Gleeble 3500): a 1st in Normandy! Only about ten Gleeble simulators exist in France, 3/4 of which are in university. It makes it possible to meet the highest requirements in terms of thermomechanical characterization.

Our competencie

The team has 3 experts and 1 manager for materials and tribology:

- Margaux Marnier, doctor and engineer in Materials – in charge of the laboratory.

- Aurélie Achille, heat treatment expert – engineering manager.

- Eymard Houra-Komba, doctor and engineer in Tribology.

- Sylvain Desquesne, Materials engineering manager.

Two contact persons for your project

Thierry-Olivier Magon,

CED manager.

Thierry-olivier.magon@normandie.cci.fr

Tél. : 06 78 80 99 94.

Margaux Marnier,

Laboratory manager of the Materials Collaborative Platform.

ced-materiaux@normandie.cci.fr

Tél. : 06 01 59 08 43

Margaux Marnier, Laboratory manager, supports you in all phases of your project, from simple testing to expertise, until the support to reach a solution.

- Definition of your specifications

- Feasibility study

- Carrying out the test in accordance with your expectations and regulatory requirements …

All in strict compliance with:

- Confidentiality: layout of the CED premises and independent preparation rooms designed to guarantee the confidentiality of the tests (limited and controlled access).

- Your deadlines (responsiveness and flexibility of schedules).